Science fiction once again is poised to invade our industry, but unlike drones and robots, this latest advance may come straight out of your old Biology 101 textbook. (Better dust it off!)

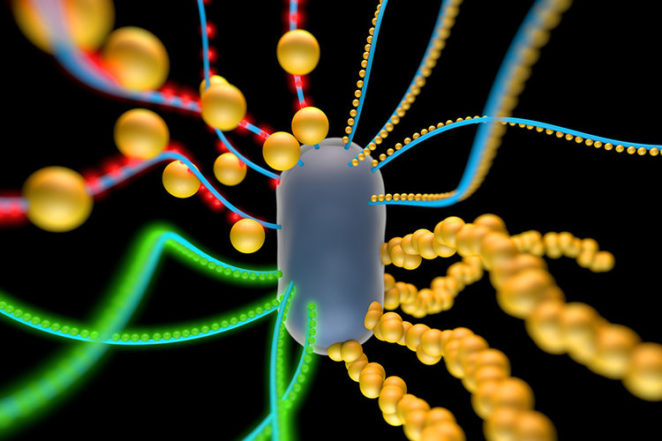

In an effort to develop construction materials capable of repairing themselves, the U.S. Dept. of Defense’s Advanced Research Projects Agency (DARPA) has launched an Engineered Living Materials (ELM) program intended to create components that combine the structural properties of traditional materials like steel and concrete with the resilient, renewable attributes of living systems. Think along the lines of manipulating living organisms like bone, skin, tree bark, and coral. That’s what DARPA is after.

“The structural materials currently used to construct homes, buildings, and infrastructure are expensive to produce and transport, and wear out due to age and damage, and have to respond to changes in their immediate surroundings,” the agency explained in announcing the program. Living biological materials have attributes that out-perform non-living materials, in that they can be grown where needed, self repair when damaged, and respond to changes in their surroundings, said DARPA.

- To read about earlier industry efforts to develop ‘self-healing’ concrete, click here.

“The vision of the ELM program is to grow materials on demand where they are needed,” said Justin Gallivan, ELM program manager. “Imagine instead of shipping finished materials, we can ship precursors that rapidly grow them on site using local resources. And, since the materials will be alive, they will be able to respond to changes in their environment and heal themselves [when] damaged.”

In the residential market alone, DARPA envisions chimneys that heal from within, roofing that breathes to control airflow, surfaces that don’t fade, and driveways that eat oil after spills, and more.

With all that in mind, DARPA this month will develop and submit a proposal that breaks down the cost of the program and designates ELM as DoD’s intellectual property. From there, ELM will construct hybrid materials that can be rapidly grown outside of a factory, according to a statement from DARPA

According to DARPA:

- The long-term objective of the ELM program is to develop an ability to engineer structural properties directly into the genomes of biological systems so that neither scaffolds nor external development cues are needed for an organism to realize the desired shape and properties. Achieving this goal will require significant breakthroughs in scientists’ understanding of developmental pathways and how those pathways direct the three-dimensional development of multicellular systems.

Although ELM isn’t totally new — various initiatives having rendered biological materials such as fungal mycellum, and some bacteria into structural uses — resulting products like wood are rendered inert by the manufacturing process. By comparison, ELM “seeks to merge the best features of existing technologies [like 3D printing] and build on them to create hybrid materials comprised of non-living scaffolds that give structure and support the long-term viability of engineered living cells.”

“Is this something you’ll see on store shelves anytime soon? Probably not… we’re seeking an aperture to the future”

Longer term, ELM plans to develop methods to engineer structural properties directly into the genomes of biological systems to achieve desired shapes and properties without scaffolds or development cues.

Of course, the program has its work cut out for it. “Is this something you’ll see on store shelves anytime soon? Probably not,” Gallivan told BuiltWorlds. “We’re seeking is to open an aperture to the future.”

Among other hurdles, current technology is incapable of regulating the size and shapes living materials for purposes of construction. To solicit ideas, DARPA also has issued a “Broad Agency Announcement” seeking research proposals from across multiple industries to aid the effort.

bio-bricks, coral roots

DARPA has acknowledged that recent advances in the development of “bio bricks” in part helped to propel the launch of ELM. Chief among such work is bioMASON, a 20-person biotech firm based in Research Triangle Park NC, where it is “growing” bricks by mixing sand and bacterial microorganisms.

What inspired bioMASON? Coral reefs.

Co-founder and architect Ginger Krier Dosier‘s purported fascination with coral and the manner in which it withstands water and erosion is the source of it all. Using a method known as biocementation, bioMASON injects sand with microorganisms to stimulate activity similar to that which produces coral. Manufacture begins by infusing sand-filled molds with Sporosarcina pasteurii, bacteria that enfold individual grains of sand, resulting in nuclei that prompt formation of surrounding calcium carbonate crystals. To further boost growth, the process adds water rich in calcium ions. Manufacture is complete once crystals have grown to a size sufficient to eliminate gaps among the sand grains.

The process requires three to five days before formation of the coral-like bricks is complete. So the firm reportedly makes 5,000 bricks every two days, modest by conventional masonry standards, though rates could increase. Having been evaluated for physical strength properties by third-party test labs, the product received results comparable to the performance of traditional masonry, claims bioMASON. Accordingly, it potentially could serve as a substitute for conventional brick in applications involving homes, commercial buildings, walls, floors, etc.

Of course, whether the bio-brick meets widespread acceptance remains to be seen, but the startup does have considerable venture backing. In 2013, bioMASON received a $1.5 million check from Acorn Innovestments, plus $2.8 million in additional seed funding, grants, and other awards. To date, it reportedly has signed licensing agreements with two U.S. material suppliers, and is in negotiations with others, including multiple suppliers located in Europe.

Of note, bioMASON doesn’t claim that its brick is “self-healing”… just highly sustainable.

“An estimated 1.23 trillion bricks are manufactured each year, resulting in approximately 800 million tons of carbon emissions due to fossil fuels required in the firing process,” states the bioMASON website. “We formed bioMASON because we believe there is a better solution for reducing CO2 emissions generated by global masonry manufacture.”

So, take notice, CO2. There appears to be a new front opening up in the war on carbon emissions. That’s language in which DoD and DARPA are certainly fluent.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.