Last month, Rob Risany, worldwide innovation executive for IBM Watson IoT, stopped by the BuiltWorlds at last month’s Data-Driven Design event and asked: “If I can ask Siri for directions, why can’t I walk up to a bulldozer and ask it how much life it has left on its treads?”

Risany was half-joking. But his point holds true — the Internet of Things (IoT) is increasing the connectivity that drives communication between us and our built technologies, letting us schedule proactive maintenance, optimize efficiency, track working conditions, and compile the information needed to create advanced buildings.

(For more on what IoT is and how it works, check out this article from one of our contributors.)

Although IoT isn’t new, it’s only recently been discussed at length in the built industry. With all the hype around the term, where are we seeing it in built technology today? Let’s take a look at three IoT technologies.

1. CONNECTING MACHINES

Combining the capabilities of the IoT with cloud-based analytics, GE’s Predix not only improves data reporting on a single piece of equipment but also for a whole system of machines. GE has built a reputation on building and manufacturing machines, but it now hopes to create an industrial IoT platform to improve machine performance through a renewed focus on app development (with a staff that included more than 19,000 app developers at the end of 2016). Any Predix user can build or buy from the GE app store, where users can compile and interpret data through a single pipeline.

GE CEO Jeff Immelt, in an interview with McKinsey & Company:

“We’ve made the decision that we’re going to try to be both a platform company and an application company. So we have a platform called Predix, and we’re building applications on top of that….And we’re opening up our platform to our customers.”

Using these apps, customers can leverage their analytics in advanced ways. Sensors, for example, can easily be added to most types of equipment, from small devices to fleets of trucks, and the growing portfolio of apps can track increasingly complex variables, including management tools for lighting and HVAC systems or applications for maintenance optimization.

We see this platform as a reinforcement of the IoT trend to make operations proactive, not reactive.

2. FIELD TO OFFICE

You might have briefly read about PlanGrid’s brand new Field Reports tool here, last week. The main software platform connects contractors and owners for collaboration on blueprints, RFIs, and other documents via mobile or desktop. Field Reports, however, is designed specifically for mobile use.

Early user Giles Raymond of Canada-based Progest Construction used the new app to tackle daily jobsite reports, according to a PlanGrid press release. “Superintendents can fill out the reports without having to log out of the application and use pictures, snapshots, and attachments already in place and always up-to-date. Best of all, when the jobsite locks up in the late afternoon, all the information is instantly available to the head office.”

We’ve seen many field documentation apps and software on the market, yes. But Field Reports seems to improve on other similar apps with features that increase speed/efficiency, including functionality that lets users fill in documents with their voice, in addition to basic features such as photo uploads, autofill, offline reporting, and Siri app control integration.

3. JOBSITE SAFETY

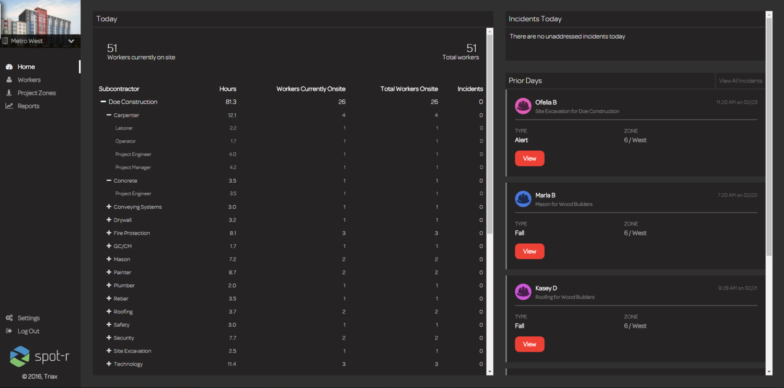

Triax Technologies’ spot-r is the latest in wearable IoT sensor technology. The device mitigates risk on the jobsite by tracking workers in real-time — using location and site operations metrics to help reduce response time in the event of a safety emergency.

President and co-founder Chad Hollingsworth spoke at our Summit last month and was featured in one of our videos, here.

Where IoT comes in: The technology breaks up the jobsite into more manageable zones, and if it senses a fall or other safety issue, it provides automatic incident alerts. Its location tracking also automatically records man hours (eliminating manual timesheet entry and cost coding) that wirelessly transfer into construction management platforms, such as Procore. No doubt we’ll see even more in wearable IoT devices for the jobsite in the near future.

Discussion

Be the first to leave a comment.

You must be a member of the BuiltWorlds community to join the discussion.